Concrete

nations largest network

Why Choose Tokyo Supermix Ready Mix Concrete

With over decades of expertise, TOKYO SUPERMIX is supplied to thousands of construction sites landwide, enabling them to expand their construction capabilities to stand the test of time. TOKYO SUPERMIX is proud to be the trusted choice of leading construction firms and building consultants, not only for local projects but also for multinational collaborations that have redefined the country’s construction landscape. On many fronts, we have been the first and only supplier, with the ability to meet some of the demanding standards set by international developers behind landmark construction projects in Sri Lanka.

Our strengths have been identified under three main categories which ensure the quality, workability, strength and durability of TOKYO SUPERMIX.

Our Components

TOKYO SUPERMIX, the nation’s most trusted brand of Ready Mix Concrete is produced by the TOKYO CEMENT GROUP: the leading manufacturer of high quality cement. Unlike any other ready-mix manufacturer in Sri Lanka, this allows for unprecedented vertical integration and total control over our entire production process.

Every concrete solution we produce is made using highest quality raw materials with BS882, BS1881 and SLS107 certification, continuously tested and sourced from trusted suppliers. Manufacturing is done in PLC controlled concrete mixing batching plants, equipped with state-of-the-art machinery. The superiority of the concrete thus produced is assured further, by following an ISO 9001 certified concrete batching process.

Our commitment to use only NIPPON CEMENT PRO, the certified leader of the cement market, is what assures TOKYO SUPERMIX’s consistent quality.

NIPPON CEMENT PRO is a special cement made with clinker imported from Japan which is especially designed for high rise buildings, including super-structures.

This has enabled TOKYO SUPERMIX to successfully produce the ultra-high strength grades of Ready Mix Concrete available in Sri Lanka, such as Grade 100, far exceeding the strength limits of our nearest competitors yet to reach even Grade 70

TOKYO SUPERMIX uses river sand and manufactured sand which assures the concrete to maintain its quality.

Manufactured sand and coarse aggregate also enables us to standardize the particle sizes to further optimize the mix.

TOKYO SUPERMIX guarantees that sea sand is not used in any of our solution mixes, as it can compromise the quality and strength of the concrete.

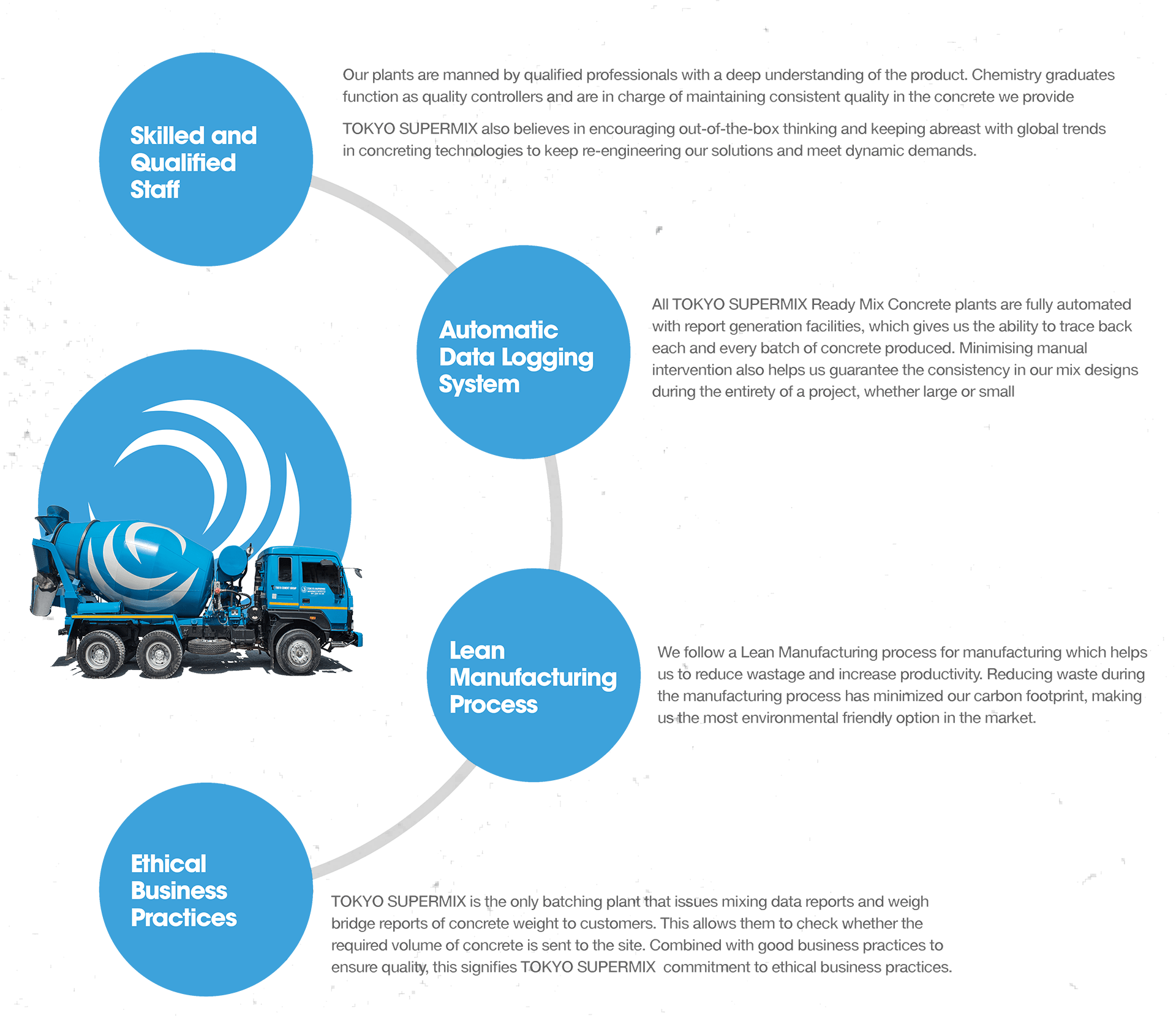

Our People and processes

To ensure that we deliver on our promise, we employ a range of quality control mechanisms, from supplier plant evaluations to close-frequency testing of raw materials all the way up to final product prototypes. All our batching plants are accompanied by hi-tech concrete formulating and testing laboratories, to provide unparalleled transparency into what we produce and deliver to you.

Our Batching Plant and Equipment

The fully automated manufacturing process is monitored via a state-of-the-art software system, that takes care of mixing the right quantities of the right material for guaranteed consistency. Furthermore, we are equipped with weigh-bridges which can generate verifiable weight records to ensure the accuracy of material input.

Cement and fly ash is stored separately to prevent material contamination that can impact the mix design. In addition, we also have ice, flaked ice and chilled water storage facilities to manufacture special solution mixes such as temperature controlled concrete. All plants are supported by backup generators to ensure an uninterrupted power supply which is mandatory during large scale batch processing.

What sets us above the board is our fastest growing and farthest spread supply network, serviced by the largest fleet of concrete mixing trucks and pump cars, reaching all parts of the island. Comprising of pump cars, stationary pumps and bulk cement carriers, our fleet also includes over 100 truck mixers with special insulated drums to transport temperature controlled concrete to various sites. We are proud of our strong supply fleet which provides an unmatched advantage to builders, introducing just-in-time delivery to the Sri Lankan construction industry.

TOKYO SUPEMIX Ready Mix Concrete plants around the country are ISO 9001 certified from Certification International (CI) UK with accreditation from United Kingdom Accreditation Service (UKAS).

Recommended Usage