TOKYO SUPERFIX is a NON-SHRINKING CONSTRUCTION REPAIR GROUT specially formulated for general civil engineering work. Consisting of cement, graded aggregate and special chemical additives blended to provide high early strength, this Non-Shrinking Construction Repair Grout is recommended for anchor bolting, repair work and basic mortar work.

The unique non-shrink feature of TOKYO SUPERFIX CONSTRUCTION REPAIR GROUT makes it ideal to use when completely filling any voids between a base plate and a substrate, such as the grouting of a stanchions and machinery base plates.

TOKYO SUPERFIX CONSTRUCTION REPAIR GROUT comes to as a ready-to-use dry powder and all you have to do is ‘Just add water’ as instructed to get flowing non-shrink grout. The special formula uses a minimum quantity of water allowing for a higher early strength. The graded aggregate component allows for a uniform mixing and produces a consistent grout every time.

Recommended Usage

Application Method

Mixing

Pour 3.25 - 3.35 Liters of clean water into a bucket.

Pour 4.0 - 4.15 Liters of clean water into a bucket.

Empty the entire 25Kg bag of TOKYO SUPERMIX CONSTRUCTION REPAIR GROUT gradually in to the same bucket while mixing using a stirrer (rpm<500).

Mix thoroughly for 3-5 mins into smooth workale paste.

Use SUPERFIX within 1 hour after mixing.

Application

Clean and remove all loose materials, oil, grease and other impurities on the area to be grouted.

The area should be flushed and soaked with clean water and prior to grouting, remove all standing water.

Trowel

Apply with a trowel ont the area to be grouted.

Flowable

Pour the grout on the area.

Eliminate the air bubbles by light rodding.

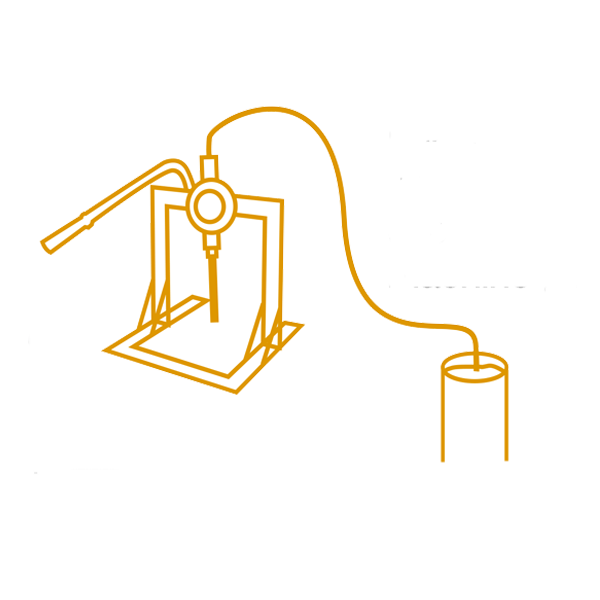

For filling holes on precast concrete/tensioned concrete, use a proper pumping machine (pressure grouting).

Protect the fresh grout from direct sunlight and wind to prevent the plastic shrinkage due to loss of moisture.

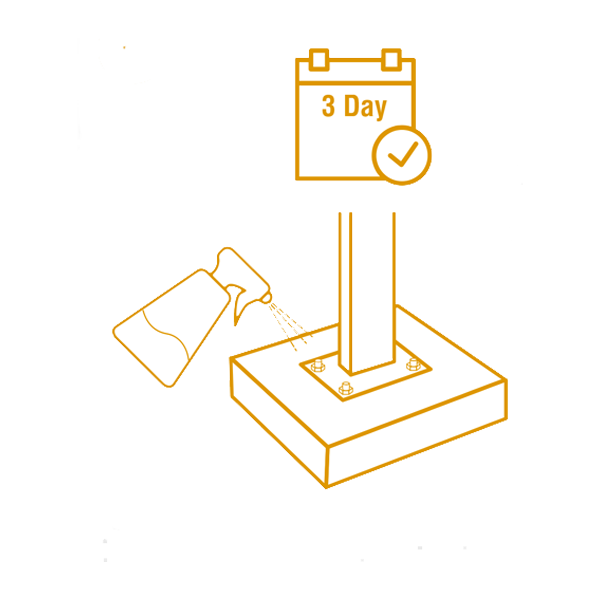

At least 03 days damp curing is essential to control the non-shrink properties and the strength.

Other Notes

Do not add cement or any other material.

Use chilled water for mixing the grout in hot weather conditions.

For pouring greater than 4-inch thickness, use 5-10 mm, clean aggregate. You can use up to 35% aggregate by weight of TOKTO SUPERFIX.

For further instructions please contact our hotline